Quality Measurement and Control Systems for Textile Industry

Seltek Quality Measurement and Control Systems (QCS) are used for different applications in textile industry such as:

- Imitation suede

- Woven fabric

These systems measure certain quality parameters of the textile products on-line such as:

- Basis weight (grammage)

- Moisture

- Coat weight

- Fiber weight

- Thickness

- Fiber blend

Nucleonic, near infrared, microwave, laser, etc. principles are used for design of these sensors. Measurements are mostly non-contact type.

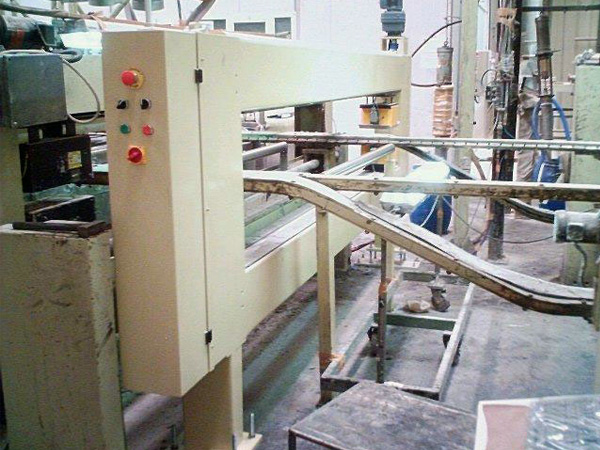

O-Frame is the most common scanner used. Single beam scanners and C-Frame scanners are also available. Single point / non-scanning fabric weight measurement systems can be provided as well.

For imitation suede lines, multi scanner architecture and differential measurement technology is employed. First scanner measures the basis weight of the fabric. Second scanner measures fabric + glue weight and the subtraction of these two measurements gives glue weight. Machine direction and cross direction glue weight is controlled automatically by moving blade coater actuators. Fibre weight is the difference between the third and the second scanner; third scanner measuring fabric + glue + fibre weight. Fiber weight is controlled by speed of the drums.

Electronics enjoy a distributed architecture and the cabling between the frame and the main CPU is minimal, being restricted to Ethernet cable and power cable.

Machine Direction Controls as well as Cross Direction Controls are available.

HMI (Human Machine Interface) is operator friendly. Fast and slow trend plots, profile pages, recipe page, rich maintenance page, controls page, roll report page, alarm and event log pages are all very easy to learn and self guiding. Roll data is stored numerically in MS SQL® database, which can be converted to Excel® format for use by mill staff.