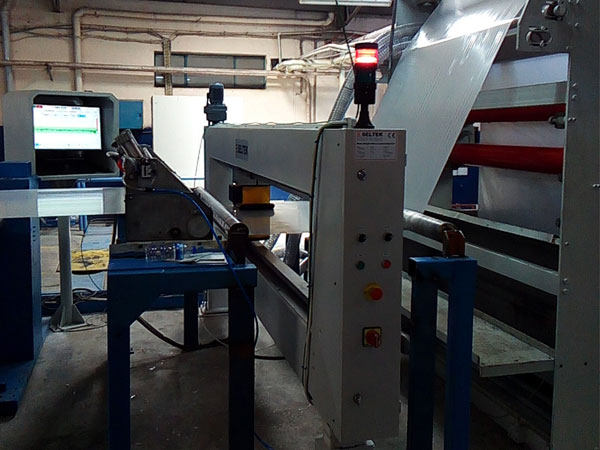

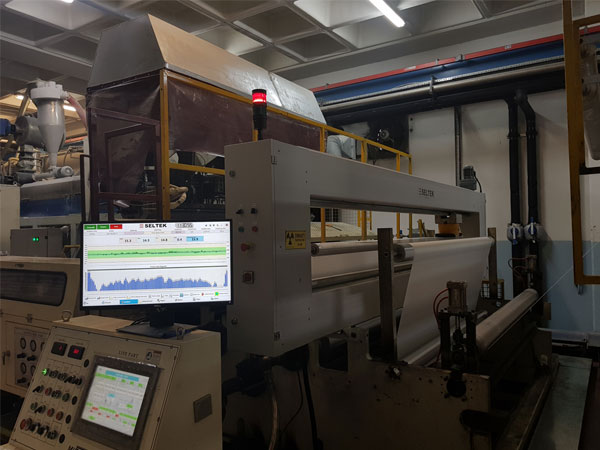

Quality Measurement and Control Systems for Plastics Industry

Seltek Quality Measurement and Control Systems (QCS) are used for different applications in Plastics industry such as:

- Cast Film Lines

- BOPP lines

- Sheet extrusion lines

- Foam production lines

These systems measure certain quality parameters of the plastic products on-line such as:

- Total thickness

- Layer thickness

Hybrid, Nucleonic and X-Ray principles are used for design of these sensors. Measurements are non-contact type.

Our Nucleonic and X-Ray sensors can measure all types of films at any thickness in very harsh environments. The accuracy stands at the level of submicron. Our 4.99kV Soft X-Ray sensor is regulation free. It does not require any administrative authorization in most countries.

The repeatability and reproducibility are excellent in all of our sensors.

Machine Direction Controls as well as Cross Direction Controls are available.

HMI (Human Machine Interface) is operator friendly. Fast and slow trend plots, profile pages, recipe page, rich maintenance page, controls page, roll report page, alarm and event log pages are all very easy to learn and self guiding. Roll data is stored numerically in MS SQL® database, which can be converted to Excel® format for use by mill staff.